UV Laser Marking Machine

Model: SY-U2/U3/U5

Laser Power: 2W/3W/5W

Working area: 110mmx110mm(standard)

UV laser marking machine

Machine Features

1. The high beam quality and light spot is very small, can realize the ultra fine and precise engraving;

2. Perfect marking quality: 355 nm wavelength output to reduce the thermal effect of machined part; high precision galvanometer marking head, fine marking effect and it’s able to repeatable processing; High precision light spot ensure the perfect marking results; Marking process non-contact, marking effect is permanent;

3. Heat affected area is very small, there will be no heating effect, material is not deform and burning;

4. Fast marking speed, and high efficiency

5. The whole machine performance is stable, small volume and low power consumption.

6. More suitable to process the materials of big reaction thermal radiation; Cooperate with production line, automatic up-down , and automatic feeding and unloading.

Technical data

Model: SY-U2/U3/U5

Laser power: 2W/3W/5W

Laser wavelength: 355nm

Beam quality: M2 <1.1

Laser power output: 0~100% continuously adjustable

Laser output frequency: 5KHz~80KHz continuously adjustable

power stability (8h): <±1%rms

Pulse width: 10-50ns

Focus light spot diameter: <0.01mm

Marking speed: 800 characters per second

Minimum width: ≤0.005mm

Minimum character: 0.15mm

Repeat accuracy: ±0.003mm

Production rate: 99.9%

Laser generator: originally imported module

Cooling: Water cooling

Environment temperature: 15℃~35℃

Voltage: 220V/50Hz

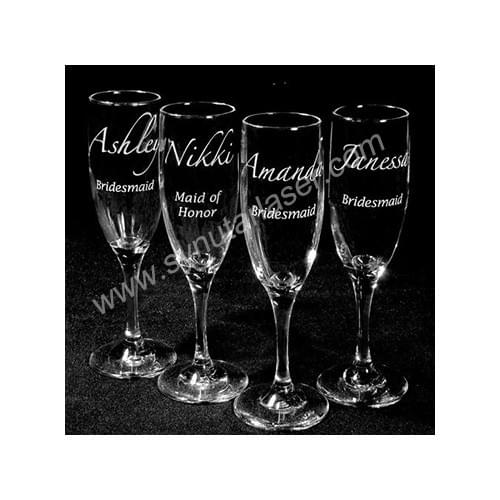

Applicable materials

High-end electronic logo marking: charger, wires, mobile phone accessories, computer accessories; Food, PVC pipes, pharmaceutical packaging materials (such as HDPE, PO, PP) marking; Flexible PCB marking; Metal or nonmetal coating removal; Porous silicon wafers and the blind hole processing and scribing; Fire prevention materials marking; Other plastic material marking.